Maul Mfg - YS Controls is a manufacturing company located in Orange County, California. We provide electromechanical assembly and test services, CNC machining services, and solenoids and valves for military, aerospace, and industrial applications.

About YS Controls

YS Controls has supplied fluid, pneumatic, and mechanical control components to the Military/Aerospace industry since 1989. Our coils, solenoids, and valves are typically built to military specifications and are for extreme environments, including internal pressures to 5000 psi and beyond. We manufacture customer designs supporting customer product optimization using electromagnetic simulation and rapid in-house prototyping to deliver the highest force and lowest energy consumption in the smallest possible package. Applications include DoD production programs such as C-17, C-130, F-16, F-18, H-1, JDAM, M-1, V-22 and many more.

About Maul Mfg

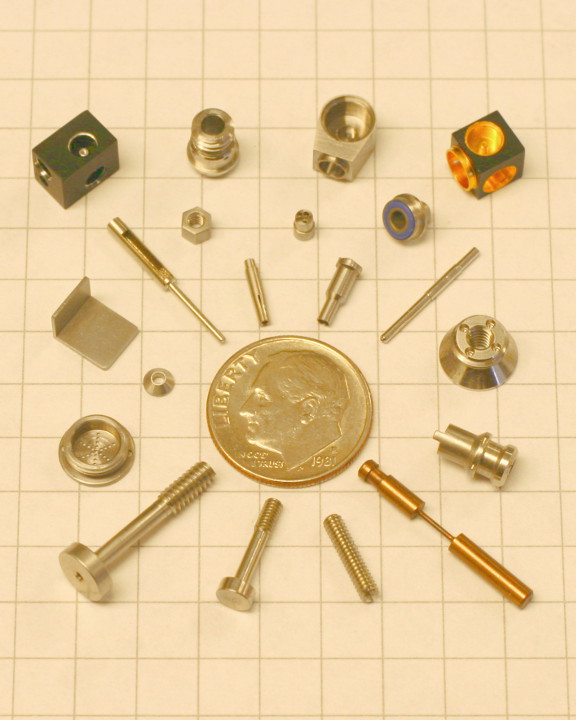

Maul Mfg., Inc is a supplier of precision machined and finished hardware primarily for high technology aerospace and industrial applications such as gyroscopes, accelerometers, transducers, power plant turbines, weapons, solenoids, and motors since 1978. We specialize in intricate, tight tolerance (commonly < .001") and miniature part machining from Inconel, Titanium, Tungsten, Stainless, Aluminum, Brass and many more materials. We also manage subcontract processes such as plating, anodizing, painting, lapping, honing, and grinding. Past DoD production programs include Hellfire and Paveway.

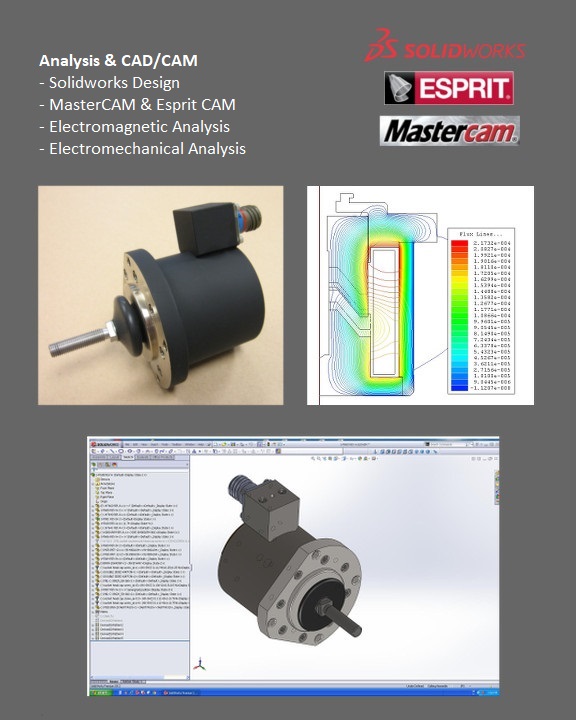

Manufacturing Engineering Tools

– Solidworks 3D Mechanical Design

– MasterCAM and Esprit Computer Aided Design & Manufacturing

for CNC

– Finite Element Electromagnetic Field Simulation &

Electromechanical Analysis

– Value Engineering, 6 sigma techniques

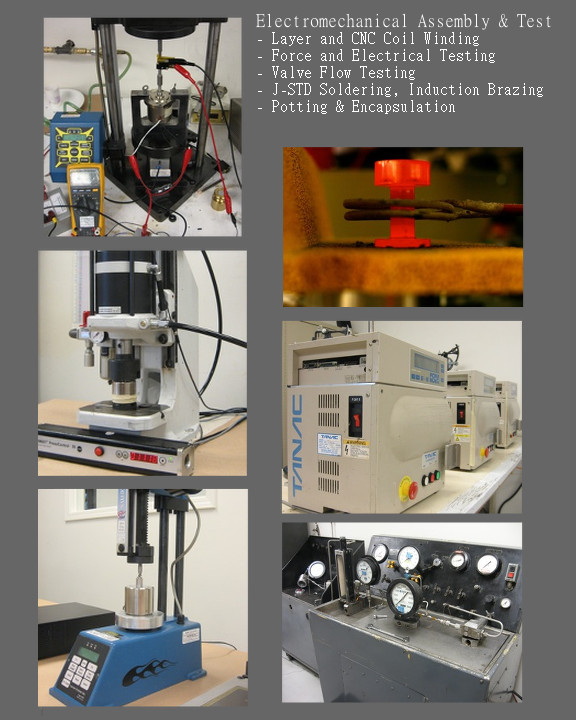

Assembly & Test Capabilities

– Coil winding (CNC &

precision layer wind)

– Soldering (hand & induction)

– J-STD-001 soldering

– Potting/encapsulation, vacuum de-air

– Induction brazing

– Electrical testing, force testing

– Static and flow testing (fuel, hydraulic, pneumatic)

– Heat treating, vacuum baking

– Torquing, wire coil inserts, press fits, crimping

Machining Capabilities

- "Lights out"

– Tsugami SS20 20mm Swiss machining center with 12 foot bar loader down to 0.030 inch diameter

– Okuma Multus B200W B-axis articulating spindle multi-function (lathe/mill) machining center with sub-spindle, Y-axis, and bar feeder

– Okuma Genos L300-MYW 25 tool multi-function (lathe/mill) machining center with sub-spindle, Y-axis, and bar loader

– Mori Seiki NL2500SY/700 35 tool multi-function (lathe/mill) machining center with sub-spindle, Y-axis, and bar loader

– CNC mills vertical and horizontal up to 22” travel

– CNC lathes up to 2 5/8” bar feed, 10” chuck

– Parlec tool presetter

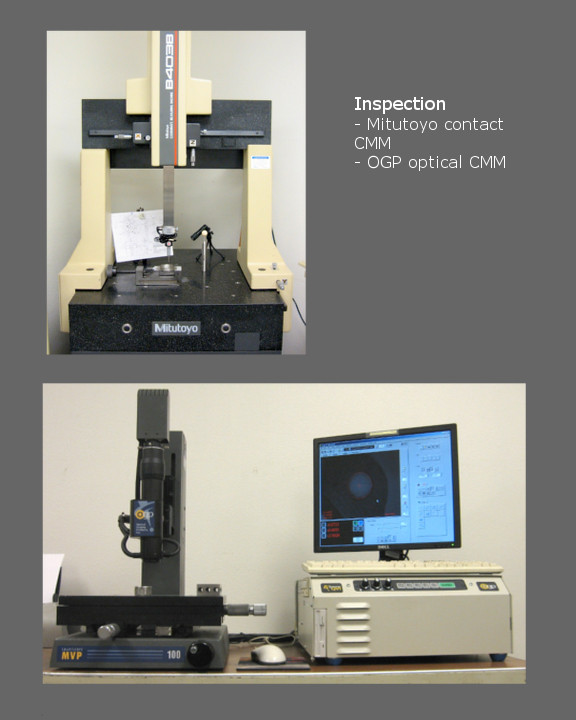

Inspection Capabilities

– Zeiss five axis

programmable CNC contact probe Coordinate Measuring Machine (CMM)

– OGP 3D programmable optical measurement and inspection system

– Mitutoyo surface profilometer

– Myriad of micrometers, gauges, etc.